As an automation integrator, I understand the importance of seamlessly integrating various components and systems to optimize efficiency and productivity. By leveraging advanced technologies and expertise, automation integrators play a crucial role in streamlining processes, reducing costs, and enhancing durability.

The Value of Automation Integrator

An automation integrator acts as a bridge between different systems, ensuring smooth communication and coordination among them. With their deep understanding of complex industrial processes, they design customized solutions that meet specific requirements while maximizing performance.

By implementing automation solutions, businesses can achieve higher levels of precision, accuracy, and consistency. This not only enhances product quality but also reduces waste and rework. Moreover, by automating repetitive tasks through robotics or software applications developed by an integration specialist like myself at Solidot Electronic Technology (SET), companies can significantly improve operational efficiency.

Solidot Electronic Technology: A Trusted Partner

At SET, we pride ourselves on being one of the leading providers of automation integration services. Our team consists of highly skilled professionals who possess extensive knowledge in diverse industries such as manufacturing, logistics, energy management systems (EMS), etc.

We collaborate closely with our clients to understand their unique challenges and goals. Through comprehensive analysis and evaluation processes tailored to each project’s needs, we develop innovative strategies for seamless integration that enhance durability while minimizing costs.

In addition to our technical expertise in hardware/software integration projects involving PLCs (Programmable Logic Controllers) or SCADA (Supervisory Control And Data Acquisition) systems; we excel at incorporating cutting-edge technologies like IoT (Internet of Things) devices into existing infrastructures for real-time data monitoring & analysis purposes.

The Advantages of Fieldbus Devices Integration

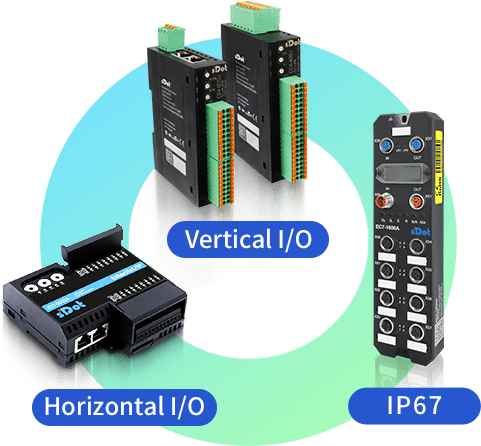

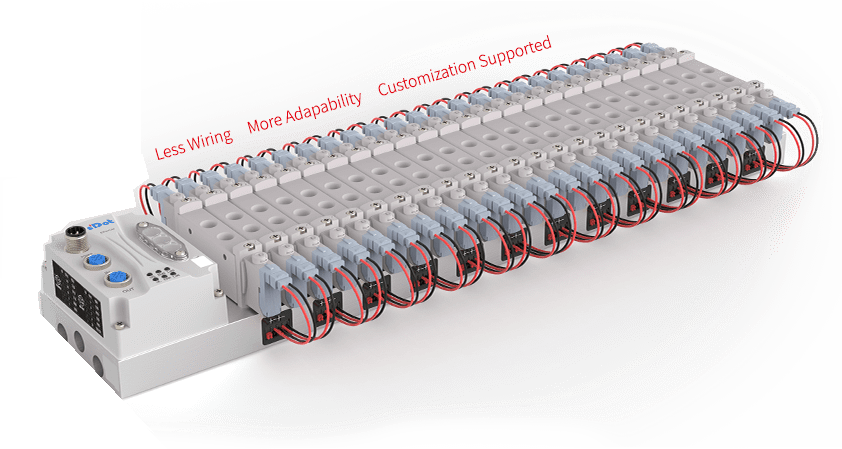

fieldbus devices, such as sensors and actuators, are essential components in industrial automation systems. By integrating these devices into a unified network architecture, businesses can achieve enhanced control and monitoring capabilities.

Automation integrators like myself have the expertise to seamlessly integrate fieldbus devices with existing control systems. This integration enables real-time data exchange between different components, facilitating faster decision-making processes and reducing downtime.

In addition to improved efficiency, fieldbus device integration also offers cost savings by eliminating the need for excessive wiring and reducing maintenance efforts. Furthermore, it allows for scalability and flexibility in adapting to future technological advancements or system expansions.

The Conclusion

Automation integrators play a vital role in achieving durability and cost efficiency through seamless integration of various components and systems. Their expertise ensures optimized performance while minimizing operational costs. At Solidot Electronic Technology (SET), we pride ourselves on being trusted partners who deliver tailored solutions that enhance productivity, reliability, and sustainability for our clients’ businesses.