In today’s fast-paced industrial landscape, achieving optimal performance and precision is crucial for businesses. One technology that has revolutionized automation processes is the servo drive system. In this guide, I will delve into the intricacies of servo drive systems and their design, shedding light on how they can enhance your operations.

The Power of Servo Drive Systems

Servo drive systems are advanced control mechanisms that enable precise motion control in various applications. By utilizing feedback signals from sensors, these systems continuously adjust motor speed, torque, and position to achieve unparalleled accuracy. Whether it’s robotics, CNC machines, or packaging equipment – servo drive systems offer unrivaled performance.

Elevating Performance with Servo Modules

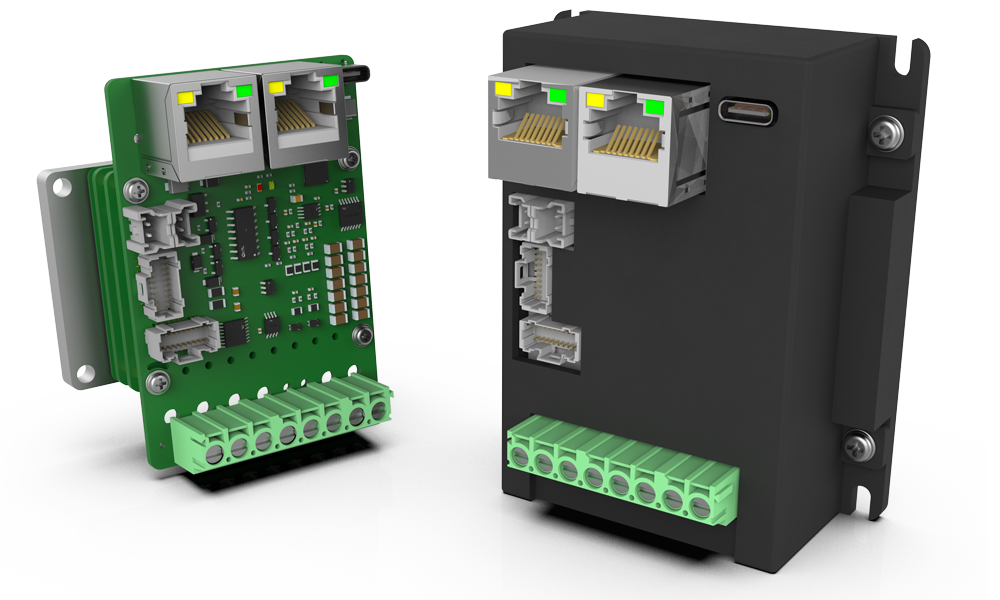

A key component within a servo drive system is the servo module. These modules act as intermediaries between the controller and motor by converting electrical signals into mechanical motion. With their compact size and high power density capabilities, servo modules provide exceptional responsiveness while minimizing energy consumption.

The Integration Advantage: Integrated Servo Motors

integrated servo motors take efficiency to new heights by combining both the motor and driver components into a single unit. This integration eliminates complex wiring connections while reducing space requirements in your machinery setup. Furthermore, integrated servo motors simplify installation procedures without compromising on performance or reliability.

Conclusion: Unleashing Your System’s Potential

In conclusion, investing in a well-designed servo drive system can significantly enhance your business operations by delivering unmatched precision and productivity gains across various industries. The synergy between powerful servo drives, efficient modules, and integrated motors ensures seamless integration within existing setups while unlocking new possibilities for automation excellence.